Sustainable thanks to the AMONUM chiller - Eco-refrigeration for industrial processes

Precise cooling with very narrow temperature tolerances and the smallest possible carbon footprint: for many planners and operators, this describes their perfect refrigeration supply. ENGIE Refrigeration meets these requirements in a sustainable manner with its AMONUM chiller. This model uses the natural refrigerant ammonia and is thus extremely eco-friendly.

Efficient, compact, sustainable – these three properties characterise the AMONUM chillers. The series has been part of the ENGIE Refrigeration portfolio since 2014 and meets the stringent requirements of the ‘zero carbon’ strategy of the French ENGIE Group, the parent company of the refrigeration and heating specialist. As the name ‘AMONUM’ reveals, the chiller uses the natural refrigerant ammonia. This offers a range of benefits for all planners and operating companies seeking an especially eco-friendly refrigeration supply.

Ammonia makes the AMONUM eco-friendly

Ammonia, technical name NH3 or R717, is a cost-effective and readily available natural product. It has been used as a refrigerant for more than 120 years and is now the most commonly used natural refrigerant worldwide. Its specific characteristics are convincing: ammonia has excellent thermodynamic properties and an exceedingly favourable pressure situation. It also has a very high volumetric refrigerating capacity, so the same refrigeration capacity can be achieved with a smaller refrigerant volume flow conveyed by the compressor. This makes it possible to achieve a higher energy efficiency ratio (EER) than with alternative refrigerants. Last but not least, ammonia has no harmful effects on the ozone layer. Both its ozone depletion potential (ODP) and its global warming potential (GWP) are zero. In spite of all these advantages, there are some reservations regarding the use of ammonia. It is flammable when mixed with air in specific mixing ratios and is classified as Water Hazard Class 2. Companies operating ammonia refrigeration systems must therefore meet strict legal requirements and perform regular safety inspections, among other things. With these measures, the risks involved in the use of ammonia as a refrigerant are however easy to manage.

AMONUM chiller: efficient, compact, sustainable

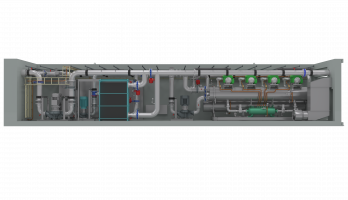

Water-cooled AMONUM chillers utilise the special benefits of ammonia as a refrigerant and also feature a sophisticated and long-established safety concept. It is possible, for example, to install a gas warning device inside the machine housing to detect even tiny leaks immediately. In addition, leaks are clearly perceptible even at low concentrations due to the characteristically biting smell of ammonia, and are thus easy to locate. Furthermore, the AMONUM also has a very high power density due to its compact design and can – as it requires less than ten kilograms of refrigerant – be placed in any non-public machine room. It is available in four performance classes from 50 to 200 kilowatts. All models are equipped with an open speed-controlled reciprocating compressor, an innovative evaporation system and a SIMATIC S7 controller for energy-optimised control of the entire periphery. AMONUM chillers thus offer especially good efficiency values under full and partial load and low operating costs – a real added value for the operating company.

Refrigeration supply minimises carbon emissions

As AMONUM chillers enable a very wide range of operating temperatures, they are suitable for numerous applications: from brine applications to -15 degrees Celsius to process cooling and air conditioning up to +15 degrees Celsius. In addition, heat recovery is possible for a condensation temperature of up to 53 degrees Celsius. Commercial and industrial ENGIE customers around the world rely on the highly functional refrigeration system, especially in the chemicals industry and in the food processing and storage sector. They benefit from eco-friendly refrigeration for their processes, which creates no carbon emissions thanks to the use of ammonia as a refrigerant and thus represents a milestone on the path towards climate neutrality.

Ammonia as a natural refrigerant – advantages at a glance:

- Climate-neutral

- Reasonably priced

- High availability

- Low energy demand for refrigeration

- Low operating costs

- High specific refrigeration capacity

- Smaller components possible

- Leaks easy to locate due to odour