AR glasses in action at ENGIE Refrigeration - how augmented reality creates added value for the refrigeration and heating industry

Around the world, everyone’s talking about augmented reality. What should our readers know about AR glasses?

Jannick Hartmann: AR glasses are smart end devices that enhance the real environment with digital content ranging from information to animations to complex 3-D models. In recent years, a lot has been happening in this field. Today's glasses – most notably the Microsoft HoloLens 2 – employ a particularly advanced technology that enables users to actively interact with virtual content by means of hand recognition sensors. This model is also in use at ENGIE Refrigeration. In contrast to virtual reality (VR) glasses, AR glasses do not completely transport users to an artificial, virtual world where there is no longer any connection to reality. Quite the opposite: Wearers of AR glasses perceive their surroundings with all their senses and can thus actively communicate with others and enrich what they see with digital content. This simplifies and improves processes.

What specific advantages do AR glasses offer?

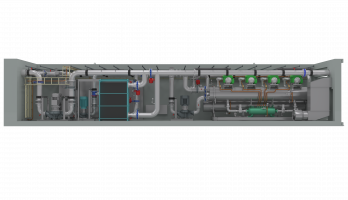

Jannick Hartmann: The actual added value is created by the software programmed on the output device, which we developed and customised together with ENGIE Refrigeration. It makes complex work processes along the value chain significantly more efficient by facilitating machine design, for example. Developers can work remotely on the hologram of a prototype at actual size because, thanks to the modern technology of AR glasses, images are no longer limited to the size of a computer screen. The realistic and detailed visualisation enhances the understanding of the machine and shows new possibilities for optimising it. It also helps customers to better visualise ENGIE Refrigeration chillers and heat pumps in their own working environment. This is because the software is capable of projecting ENGIE Refrigeration systems to any location.

Jörn Stiegelmeier: Thanks to the three-dimensional representation as a real-size hologram, it is easier to visualise and coordinate individual work steps. This can reduce corrections during development loops. In addition, it is vital that our technology is practical, fast and easy for developers to use on a daily basis. Working with AR glasses fulfils these requirements completely. That is particularly true now that we have adapted the AR application to the Microsoft HoloLens 2 together with HOLO-LIGHT to suit our needs exactly. This enables us to see even our largest machines – such as the QUANTUM Air and QUANTUM Water chillers – through the glasses at the touch of a button, without time-consuming data preparation or conversions. That's real added value!

For which industries and business sectors are AR glasses particularly well suited?

Jannick Hartmann: At the end of the day, there are potential use cases in every industry and company. A factory tour in the warehousing and logistics sector or a virtual shopping experience in retail are just two of many examples. The remote assist process for machine maintenance, in which operating companies share a real-time view of their equipment with teams of experts, has also proved itself in practice.

Jörn Stiegelmeier: For us at ENGIE Refrigeration, digital concepts and smart features are playing an increasingly important role. I would therefore like to add that other areas besides technology and development at ENGIE Refrigeration are also superbly suited for the use of AR glasses. I am thinking of production, for example, to vividly project the first prototypes into production in advance. In my opinion, augmented reality also facilitates work in service and in logistics. In addition, third-level support can assist our on-site service even better in future with the help of AR technologies. From now on, we will be working more closely on such approaches.

Where do you see the greatest challenges with such solutions?

Jannick Hartmann: On the one hand, technology leaders are faced with the challenge of representing data models of different magnitudes. In the case of ENGIE Refrigeration, these are very extensive and complex due to the dimensions of the various plants. On the other hand, data security must never be neglected. That is why we stream the CAD file to the end device, thus ensuring that it never leaves ENGIE Refrigeration's IT infrastructure. This is how we guarantee absolute data security. Furthermore, we place great emphasis on ensuring that all users always use the latest version of the software. We can assure this at all times through the streaming approach, whereby the application is located within ENGIE's IT infrastructure.

Mr Stiegelmeier, how did you first come up with the idea of using AR glasses at ENGIE Refrigeration?

Jörn Stiegelmeier: Those who know me personally know that I am a real technology buff and am therefore constantly on the lookout for the latest technologies with added value. I firmly believe that we can only progress as a company if we keep breaking new ground. That's why I started working on this topic back in 2017 – at a time when augmented reality in the refrigeration and heating industry was still a vision of the future. At the beginning of our collaboration with HOLO-LIGHT, it was clear to me that there was a lot of work ahead of us. That didn't deter me at all – quite the opposite, in fact. Today I can say with a clear conscience: it was worth it. If we hadn’t taken that first step back then and insisted on always being technologically up to date, we would certainly not be where we are today. As a result, ENGIE Refrigeration is now a global pioneer in our industry when it comes to augmented reality and AR glasses. And that’s something we’re of course proud of.

How would you assess the use of AR glasses at ENGIE Refrigeration so far?

Jörn Stiegelmeier: So far, we have sporadically used AR glasses in development. Now we have reached the point where we are gradually integrating them into our day-to-day work. I hope that we will succeed in getting our employees as enthusiastic about augmented reality as I am myself. At the moment, we are collaborating with HOLO-LIGHT on an intelligent solution for predictive maintenance in order to offer our customers even more efficient service in future. I can reveal one thing – we have lots of plans in the works!

What are the benefits of current and future AR applications for ENGIE Refrigeration customers?

Jörn Stiegelmeier: Our customers benefit from machines that run more efficiently than ever before. AR glasses would make it possible to spot potential weaknesses at an early stage of development and eliminate them even more quickly. Augmented reality will also help us to offer users even better services.

And how are you using augmented reality to support operating companies on their way to climate neutrality?

Jörn Stiegelmeier: The use of augmented reality is an additional trailblazer in the transition to ‘zero carbon’. With AR glasses, we may be able to avoid service trips in future. Moreover, unnecessary development loops can be reduced. This saves valuable resources such as CO2 and electricity. Together with our customers, we are thus taking a further step towards climate neutrality.

Mr Hartmann, how would you assess the use of AR glasses at ENGIE Refrigeration?

Jannick Hartmann: ENGIE Refrigeration recognised the potential and added value of augmented reality in design early on and can thus secure a competitive edge. I look forward to taking further joint steps in the technological development of applications for AR glasses and to providing ENGIE Refrigeration with the best possible support in this endeavour.

Jörn Stiegelmeier: It is true that topics such as artificial intelligence and data glasses always entail a great deal of effort. However, the collaboration with HOLO-LIGHT is always constructive, friendly and goal-oriented. My ideas are well received and are further considered and implemented by the team according to our individual requirements. Our appearance at Chillventa 2022 was unquestionably a highlight: Our presentation there with AR glasses attracted lots of visitors – and was the only one of its kind at the trade fair. Of course, that motivates us even further. There is more to come from ENGIE Refrigeration in terms of augmented reality!

Mr Hartmann and Mr Stiegelmeier, thank you for talking to us.

About Jörn Stiegelmeier

Jörn Stiegelmeier has many years of experience in the field of refrigeration and heating technology. The electrical engineer has been active in the refrigeration industry for more than ten years, eight of which he spent in a managing position at BorgWarner Cooling Systems GmbH in Markdorf. Since 2015 Jörn Stiegelmeier has been responsible for technology and development at ENGIE Refrigeration GmbH in Lindau on Lake Constance. In 2017 he became the head of the refrigeration committee of the BTGA – the Federal Industrial Association for Building Services (Bundesverband Technische Gebäudeausrüstung e. V.). Jörn Stiegelmeier is the author of several articles for national and international specialist publications and is a regular speaker at industry events such as the efficiency forums conducted by ENGIE Refrigeration GmbH and Condair GmbH.

About Jannick Hartmann

For the past five years, Jannick Hartmann has been working with Holo-Light to bring the benefits of augmented and virtual reality to a variety of industries. As Senior Sales Manager, he supports industrial enterprises in the adoption and use of these immersive technologies. He is passionate about supporting his customers in their digital transformation to enable them to achieve new levels of profitability and efficiency. He loves to demonstrate specific use cases and quickly deliver new technology solutions to his customers.