Large heat pumps as a key technology for a climate-neutral future

Why are large-scale heat pumps a key technology for a climate-neutral future and what challenges and opportunities are there for their implementation? Jörn Stiegelmeier, CTO of ENGIE Refrigeration, answers these questions in an interview.

Jörn, why do you think large-scale heat pumps are a technology of the future?

Jörn: The German government has set itself the ambitious goal of becoming climate-neutral by 2045. According to the 2021 coalition agreement, 50% of heating is to come from renewable energies by 2030. Since space heating, process heating and hot water account for about half of the total energy consumption, industrial heat pumps offer an efficient solution to supply these areas sustainably. Large-scale heat pumps are therefore a key technology for achieving climate targets while reducing dependence on fossil fuels. They enable existing heat sources such as ambient heat or waste heat from industrial processes to be efficiently utilised and converted into usable heat.

What specific challenges do you see in implementing heat pumps in industry?

Jörn: One of the biggest challenges with heat pumps is the need for an additional energy source besides electricity. Without ambient heat, wastewater heat or other heat sources, a heat pump cannot work efficiently. It is crucial to identify and use suitable heat sources. In addition, the technical and economic conditions must be right to ensure successful implementation. This includes integration into existing systems, ensuring economic viability and taking regulatory requirements into account.

What potential heat sources are available for heat pumps?

Jörn: There is a wide range of heat sources that can be used for heat pumps. These include water, geothermal heat, waste heat from industrial processes or from data centres and even sewage treatment plants. Sewage treatment plants in particular provide warm wastewater that can serve as a valuable heat source. This diversity of heat sources makes it possible to use heat pumps in a range of applications and industries, thus contributing to the energy transition.

In which areas of application do you see potential for large-scale heat pumps?

Jörn: Heat pumps are extremely versatile. They can be used for space heating, domestic hot water, process heating and in heating networks. Our heat pumps and chillers cover temperature ranges from -15 to 120 degrees and offer capacities from 50 kW to 8.5 MW. This makes them suitable for a wide range of applications and they can be used in various industrial processes and in air conditioning for buildings.

What technologies and refrigerants does ENGIE Refrigeration use in its heat pumps?

Jörn: We use a variety of heat pump series and coolants to meet a range of different requirements. These include ammonia, synthetic coolants and CO2. The choice of coolant depends on the specific application and the temperature range required. It is clear that our customers' various requirements cannot be met by just one coolant. Nevertheless, there are three significant decision criteria for choosing the right refrigerant for the respective application: safety, environmental friendliness, efficiency and cost-effectiveness.

How do you manage the challenge of reaching high temperatures with heat pumps?

Jörn: Reaching high temperatures with heat pumps is quite challenging. Often it is necessary to use a cascade of heat pumps to get from low to high temperatures. This requires careful planning and coordination of the individual components. However, by using multi-stage systems, we can meet high temperature requirements and thus cover a wide range of applications.

Can you give us some examples of industrial applications for heat pumps?

Jörn: There are numerous industrial applications for heat pumps. These include malt houses, cheese and soy milk production, abattoirs, chocolate production, timber drying and milk pasteurisation. Each of these applications has specific temperature requirements that can be met with our various heat pumps. This demonstrates the versatility of heat pumps in different applications.

Can you give us a specific example of a successful application of your heat pumps?

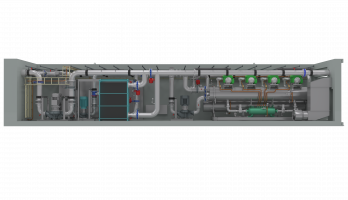

Jörn: A data centre originally required 1,950 kW of cooling capacity. We installed a QUANTUM chiller for this. The waste heat that was generated during this process could be used even more efficiently. To make optimal use of this waste heat from the cooling process, we also installed a SPECTRUM heat pump to raise the temperature of the waste heat. The cooling unit and the SPECTRUM heat pumps together generate waste heat, which supplies the heating network of a nearby biogas plant. This makes the bioprocess even more efficient and saves fuel. This illustrates how efficiently and flexibly our products can be used.

What other projects can you tell us about?

Jörn: Another noteworthy project is in Baden-Baden. Here, a thermeco2 heat pump was used to cover the heating needs of a hotel and the air conditioning and server cooling of the SWR. Incidentally, the thermeco2 high-temperature heat pump was easily integrated into the existing SWR energy centre. This project enables the end customer to save 32% CO2 and 26% of fossil fuel requirements.

Osatina in Croatia is a major food producer with more than 10,000 m² of greenhouse space. ENGIE Refrigeration supplies 2 MW of heat and 1.5 MW of cooling for the site. In addition, various technologies have been combined, including a 3.1 MW photovoltaic system, a CHP plant and several heat pumps, to ensure an efficient and sustainable energy supply.