The EU Ecodesign Directive – what do you need to know?

The EU regulates the minimum energy efficiency limit values for chillers that are used for process cooling and climate control. The regulation is related to the EU Ecodesign Directive. This directive in turn regulates the design of products that are relevant to energy consumption. What exactly has changed for owners?

What is the purpose of the Ecodesign Directive?

The EU passed the Ecodesign Directive to pursue ambitious climate targets: The aim is to reduce by 2030 the greenhouse gas emissions by at least 40 percent of what was emitted in 1990. This definitely requires energy-efficient technologies with low power consumption values. The Ecodesign Directive therefore contains individual measures for a range of product groups, among them pumps, electric motors and household fridges. “They regulate the specific requirements for the product in question. Chillers are subject to Regulation (EU) 2016/2281 for process cooling at high operating temperatures and climate control, and to Regulation (EU) 2015/1095 for process cooling at medium and low operating temperatures,” explains Marco Zetzsche, Project Manager for Thermodynamics and Mechanical Systems at ENGIE Refrigeration.

SEER and SEPR: performance indicators for energy efficiency

In concrete terms, chillers are subject to strict rules defined by means of the SEER and SEPR performance indicators, as Zetzsche explains. They express energy efficiency on the basis of a one-year usage cycle. Energy efficiency in partial load has a particularly strong influence here: “This makes sense, because chillers almost always operate in partial load; after all, design parameters such as the maximum outside temperature for 100 per cent cooling requirement occur on average just five to six hours a year,” explains Zetzsche. Minimum values have been specified for SEER and SEPR for tier 1 (in force since January 2018) and tier 2. New refrigeration system must comply with these values so they can be sold in the European Union. Tier 2 will take effect on 1 January 2021. The new EU regulations are thus setting new standards in terms of energy efficiency, and inefficient technologies may no longer be sold on the European market.

Dealers and manufacturers are responsible

Owners of chillers and end customers do not have to do anything right now. “In fact, the responsibility lies with dealers and manufacturers,” says Zetzsche. “They are obligated to specify SEER values for air conditioning chillers and SEPR values for process chillers in the product documentation.” Naturally, ENGIE Refrigeration takes this topic seriously and is absolutely transparent in terms of sustainability: when customers receive an offer, it contains the calculated SEER and SEPR values.

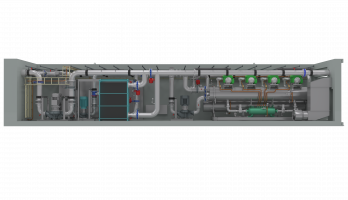

ENGIE Refrigeration chillers are energy-efficient

Products from ENGIE Refrigeration not only meet the requirements of the Ecodesign Directive, they actually exceed them. All the performance indicators of the QUANTUM, AMONUM and SPECTRUM series are significantly above the minimum SEER and SEPR values specified for tier 2. These chillers provide this high level of energy efficiency throughout their lifetimes. This is ensured by high production standards that make sure the machines are leak-tight. That means that no refrigerant escapes, and customers ultimately save energy and a lot of money. Chillers from ENGIE Refrigeration are thus among the most efficient models on the international market and are both sustainable and durable.